TRIVENI ENGINEERING - AHMEDABAD

- Home

- Triveni Engineering

- Spray Dryer

Spray Dryer

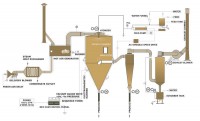

Spray drying is a continuous process that converts almost any pumpable liquid into a free flowing powder. The liquid, which can be pre-heated in order to reduce energy consumption in the drying process itself, is sprayed via an atomizer into a drying chamber where it is evaporated.

The solids content is left behind for collection and any necessary further treatment without any intermediate manual handling.

Spray drying is a highly cost-effective method of obtaining powder from heatsensitive liquids while retaining valuable nutrients, elements, active ingrediants, aromas, flavours etc.

Two drying principles are relevant for the industry. The Conical Spray Dryer (CSD) with air extraction at the base of the chamber, and the Triple-A with air extraction at the top of the chamber. Each type offers the following options:

Single-stage spray dryers with product outlet at the base, Two-stage spray dryers sending product, to an external fluid bed dryer and/or cooler, Multi-stage spray dryers sending product to an integrated fluid bed, and then into an external fluid bed dryer. and/or cooler.

Cyclone

Powder from the drying chamber is fed to one or more cyclones for primary separation from the drying air. With separation efficiency in excess of 99.5 per cent, cyclones ensure minimal powder loss as well as emissions well inside the limits of environmental regulations. Further cleaning of the drying air can be achieved using a bag filter, or a wet scrubber system.

Optimized Yield And Efficiency Scrubbers & Bag Filters

TRIVENI CIP-cleanable bag filters to replace cyclones enables lower pressure loss and increased energy savings. The filter materials can handle relatively high air outlet temperatures, and the automatic cleaning system ensures a high and constant separation efficiency. Scrubber systems are designed to achieve zero discharge of air flight, hence used as pollution controlling tool.

Customer Focus

TRIVENI can assist in designing complete spray drying system solutions and optimizing process parameters as well as plant maintenance and spare parts services.

A service and maintenance agreement with TRIVENI also ensures maximum plant uptime and timely spare parts deliveries as well as the ability to adopt fixed service budgets Test center.

TRIVENI's state-of-the-art test facility in AHMEDABAD enables customers to perform confidential product development and trials together with TRIVENI experts. Small-scale plant is also available on a rental basis for in-house laboratory trials. Process automation and control Automated process control is essential in order to optimize key process settings such as feed rate, temperature, pressure, residence time, particle size, moisture content, bulk density etc.

TRIVENI acts as a strategic development partner for leading manufacturers all over INDIA. Through close collaboration with our customers, TRIVENI promotes the development of innovative concepts and optimization of existing processes, enabling customers to introduce new products into the market as quickly and as cost effectively as possible.